Casa>Produtos>NACHI Hydraulic Pump>NACHI VARIABLE VANE PUMP VDR-1A-1A2-11

NACHI VARIABLE VANE PUMP VDR-1A-1A2-11 MODELS

Need a CAD or 3D Model?

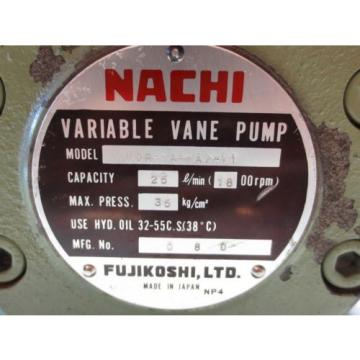

NACHI VARIABLE VANE PUMP VDR-1A-1A2-11

category

NACHI Hydraulic Pump

NACHI VARIABLE VANE PUMP VDR-1A-1A2-11 SPECIFICATIONS

NACHI VARIABLE VANE PUMP VDR-1A-1A2-11

- Unbranded/Generic

- Does Not Apply

- Does not apply

-

kamenzhang2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

kamenzhang2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Detalhes do produto

- Unbranded/Generic

- Does Not Apply

- Does not apply

NACHI VARIABLE VANE PUMP VDR-1A-1A2-11 Descrição do Produto

NACHI Pumps NACHI VARIABLE VANE PUMP VDR-1A-1A2-11

Along with constantly improving performance, industrial machines continue to become increasingly sophisticated. NACHI VARIABLE VANE PUMP VDR-1A-1A2-11 has to meet the challenge of diversifying needs. You may already appreciate the Nachi-Fujikoshi reputation for compact equipment that delivers energy efficiency, safety, and high performance. Our equipment is also constantly refined by our quest for ultimate hydraulics that combine great power with flexible motion control.

PVD Series Piston Pump

One pump discharges two equal amounts of flow to ensure shovel straightness.

Constant horsepower control with full use of engine horsepower, resulting in increased speed and power for mother machine.

Compact size enables installation in a small engine room.

PVS Series Piston Pump

Half-cylindrical swash plate for low noise and low pulsation.

Rich set of options to enable highly efficient, energy-saving equipment.

PZS Series Piston Pump

Half-cylindrical swash plate and 11 pistons for low noise and low pulsation.

Spherical valve plate for high efficiency.

Multiple string option with our IPH series inscribed gear pump.

UVN Series Unipump

Enhanced hydraulic pump and electromotor efficiency for decreased electric consumption.

Compact size for space-saving unit design.

Original connection method between pump and electromotor shaft for low noise and long life.

PVK Series Piston Pump

Constant horsepower control with full use of engine horsepower, resulting in increased speed and power for mother machine.

Load sensing control can be achieved with our DPK load sensing valve, resulting in energy savings for mother machine.

Compact size enables installation in a small engine room.

PZ Series Piston Pump

Half-cylindrical swash plate for low noise and low pulsation

Spherical valve plate for high efficiency (Employed into 3B, 4B and 6B.)

Various capacities ranging from 35 to 220cm3/rev (7 sizes in total)

Multiple string option with our IPH series inscribed gear pump.

The electro-hydraulic proportional control valve uses the proven force feed-back system for improved hysteresis, repeatability, and response.

PVS Series Piston Pump

Half-cylindrical swash plate for low noise and low pulsation

Rich set of options to enable highly efficient, energy-saving equipment.

PZS Series Piston Pump

Half-cylindrical swash plate and 11 pistons for low noise and low pulsation

Spherical valve plate for high efficiency

Multiple string option with our IPH series inscribed gear pump.

SERVICE & VALUE

Our Company is proud to support our quality products with NACHI VARIABLE VANE PUMP VDR-1A-1A2-11 services before and after the sale.

We have Regional Sales Managers that will work with you to identify opportunities, review requirements, provide training and assist with forecasting and commercial concerns. Our Industry Service Specialists will take it to the next level by providing field services such as; NACHI VARIABLE VANE PUMP VDR-1A-1A2-11 inspections, hands on training and assistance with installation, inspection, maintenance, reinstallation, field repair and/or factory reconditioning.

We can provide complete NACHI VARIABLE VANE PUMP VDR-1A-1A2-11 application review by combining the efforts of your operations and maintenance personnel with our design and application engineers. Our Industry Service Specialist’s comprehensive review of the bearings to be inspected or removed from service to determine where you will best benefit from making improvements.

This total approach of application, equipment, products and maintenance will lead to Our company’s goal of helping you establish the best practices for your specific situation resulting in the best value and return on bearing and maintenance expense through improved performance and reduced downtime.